Warehouse Management

ERPSirius WMS helps to monitor and handle the day-to-day tasks of a warehouse. allowing your organisation to control and oversee third-party logistics processes. Ideal for most types of business including freight forwarding, logistics providers, and retail outlets.

WMS is part of the Freight & Logistics module which also includes the Fleet/Transport Management and Containers handling submodule. WMS can also be used as a Yard Management Software to oversee the movement of trucks and trailers in the yard of a manufacturing facility, warehouse, or distribution centre.

WMS fully integrates with all other modules in ERPSirius.

Submodules or processes included;

- Warehouse Receipt

- Warehouse Delivery

-

- All types of items or cargo types. with quantity, weights and volumes.

- Add various charges to Warehouse Receipts and Delivery Notes including Container Handling & Storage, Demurrage, Detentions, Storage & Handling Charges.

- Add other types of charges.

- Charges can automatically produce invoices.

- Packing Management

- Manifest

- Cargo Manifest

- Freight Manifest

- Dangerous Cargo Manifest

- Out of Gauge Manifest

- Reefer Manifest

- Container Handling

- Route Planner

- Fleet/Transport Management

- Maintain transport details including maintenance and servicing schedules and history.

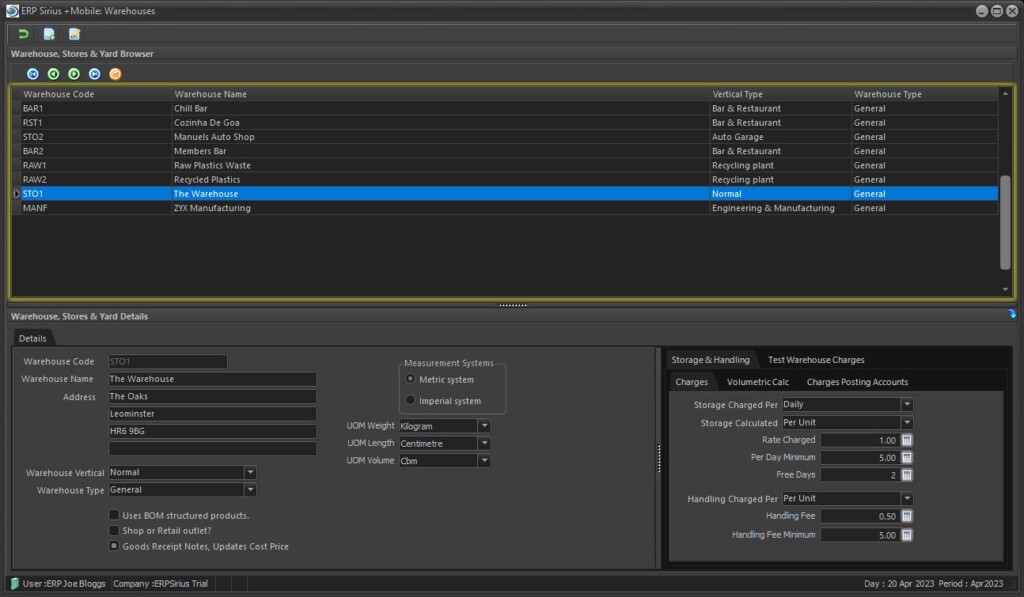

Warehouses

ERPSirius supports warehouses of all types from manufacturers, importers, exporters, wholesalers, and transport businesses to customs warehouse types. In fact whatever type of item needs to be tracked, and stored there is a warehouse type in ERPSirius for it. Below is some warehouse types.

- DISTRIBUTION CENTER

- A distribution centre holds products for a short period of time and sees a much higher velocity of products coming in and going out.

- Distribution centres are very customer-centric and are typically located close to where the end user is, so they receive products quickly and in good shape., or simple product mixing or packaging. Because a distribution centre offers more services than a warehouse, they are also equipped with much more advanced technology to facilitate the processes happening within.

- PICK, PACK, & SHIP WAREHOUSE

- In a warehouse, pick, pack, and ship is the process that happens after an order is received, either from an online store or a brick-and-mortar store. The warehouse receives a pick list of products, and finds the products within the warehouse. Next, the product is packed for shipping, labelled, and shipped to the customer.

- COLD STORAGE

- Cold storage stores temperature-sensitive items at low temperatures. Cold storage warehouses allow medicine, perishable foods, plants, cosmetics, artwork, and candles to have longer lives. Cold storage warehouses also use refrigerated shipping for inbound and outbound shipping.

- ON-DEMAND STORAGE

- On-demand warehousing connects businesses with a need for warehouse space (temporary, seasonal, or to handle spikes in sales) with warehouses that have excess space.

- BONDED WAREHOUSE

- Also called “customs” warehouses, a bonded warehouse is a building in which imported goods may be stored, manipulated, or undergo manufacturing operations without payment of duty for five years from the date of acceptance. The duty on imported goods can be very high so the bonded warehouse allows the products to be sold first, and then duty is paid from the proceeds of the sale.

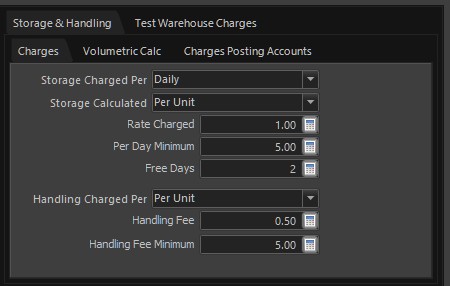

ERPSirius is able to handle different types of storage and handling charges for each warehouse and customer.

Storage costs are the amount of money incurred as a result of storing inventory. The costs could be direct or indirect money spent on the storage of goods. Storage can be charged daily, weekly, monthly, flat rate or per job or order. Storage calculation can be done per unit, weight, volume or per square unit.

The storage costs may include costs for space, rent, electricity, software, depreciation and warehouse personnel. Generally, storage costs are described as a percentage of the inventory value. Depending on the industry, the percentage value varies.

Handling fees are expenses associated with moving your product in and out of the warehouse. This includes unloading your product from a trailer or container, receiving it into the WMS, and shipping it out to your customers. Handling fees can be priced by the pallet, unit, order, weight, volume, flat rate, per job or hourly.

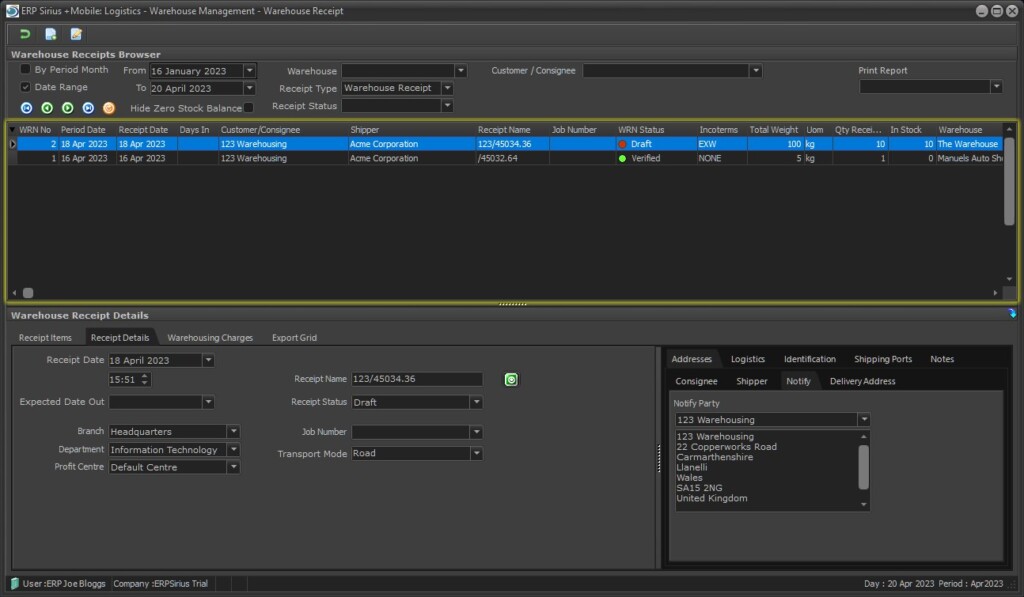

Warehouse Goods Receipt

A warehouse receipt is a document on which are itemized the goods stored in a warehouse. The receipt represents title to the goods. ERPSirus shows warehouse receipts for goods or items in the various warehouses. A range of information can be displayed from the status of the receipts to original items balances and currently in-stock balances.

Warehouse charges for storage and handling charges etc are also shown if the warehouse is setup to handle storage and handling charges. Other kinds of charges can also be applied to the goods or items.

Additional information is displayed in tabs

- Addresses Tab

- Consignee, Shipper, Notify Party, Delivery Address.

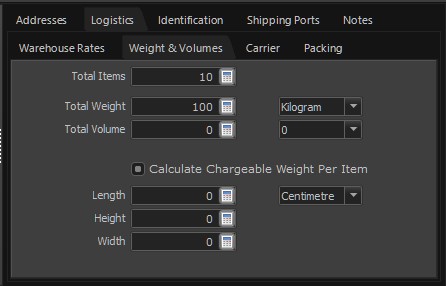

- Logistics Tab

- Warehouse Rates for goods receipt, Weight, Volumes and dimensions of items and/or whole consignment.

- Carrier information like

- M/Vessel, Bill of Lading, House Bill of Lading, Ocean Bill of Lading, Voyage Number, Inco Terms

- Packing information

- Packing structure (SOIP/SOPI), Packing Slip No

- Identification Tab

- Serial Shipping Container Code, Standard Alpha Code, Container No. , Seal No, Trailer No

- Shipping Port

- Port of Clearance, Port of Shipment, Port of Discharge, Final Destination